So with the copter design in this post, I've split it up into sections, these are mechanical, electrical and a combination of both (which is actually first) plus some extras. The mechanical section is then further spit up into rotors (and related), centre console, material (carbon fibre/fibre glass), camera mount/gimbal, bearings and then finally the electrical influences of on the mechanical design of the copter.

I'll get stuck in now. Firstly I found a competition that would be a great goal to aim for. Its called the UAV Outback Challenge and its centred around using UAVs for civil use to rescue "Outback Joe" who has injured himself. You need to find him in a roughly square kilometre. Looks fun and could be a great final year project. If I managed to get the copter working in the next year, I should hopefully be able convince uni to let me do so, otherwise I'll go a year later by myself, specially seeing its a fifty grand first prize and the first three years, no one managed to even get near without their UAVs crashing. I don't know what its been like since as there doesn't seem to be much information about previous years on their website.

I think, from going through everything in my head, I've worked out what the hardest parts of the project will be for me. These are, in no particular order:

• learning how to program ARM

• moulding fibre glass and/or carbon fibre

• SMD board manufacturing

• Optimisation (such as pitch of rotors, gap between rotors and guard and what motor to get)

I've talked about most of these in previous posts or will in this post. I haven't and won't be talking about moulding just yet though as I'm still working out what to do but I have most of the ideas on how to do this in my head. Such as creating 3D printed moulds or 3D printed objects that I can then later mould.

I have now got pretty much, the whole design in my head ready to be drawn in CAD. I won't be doing this until after exams as will take way too much time (though I say this now and no doubt I'll want to not study so do it anyway). Once I do get CAD models I'll export it into Blender 3D so I can render the pictures nicely. I have drawn some images up of the different parts (though not to scale) which I'll show below. I've also thought of a colour scheme and that is black and red as I think it will look cool!

|

| Basic sketch of ducted fan |

I've decided I am going to make the rotors ducted as it seems from what wikipedia says, that they are more efficient than open flow. I should have found this earlier but was stupid enough not to think that ducted fan was in essence what I was looking for. Now that I've decided on ducted axial flow, I can start designing how I'm going to build said duct. For example I need to workout how much of a gap between the end of the rotor and inside of the duct I leave. I also was thinking that maybe I should shape the duct/guard so that it had a wider inlet than outlet but I think that can be a revision for later and I'll just leave them vertical for now. I've read in my Fluids text book as well as on wikipedia, that I should incorporate stators to increase efficiency further and limit rotational forces. I realised a few days ago just before going to sleep that it would be best if these curved slightly to channel the fluid flow down rather than having it just hit a vertical wall. So I'm going to make these sort of a long-gated raindrop shape (picture above). These stators I'm going to put in a Y shape as it was also recommended to have a number that didn't have a common denominator with the number of blades of the rotor (I'm going to use 2 and 3 for rotor and stators retrospectively). The stators will also support the motor and be hollow so cabling can pass through them.

I've decided I am going to make the rotors ducted as it seems from what wikipedia says, that they are more efficient than open flow. I should have found this earlier but was stupid enough not to think that ducted fan was in essence what I was looking for. Now that I've decided on ducted axial flow, I can start designing how I'm going to build said duct. For example I need to workout how much of a gap between the end of the rotor and inside of the duct I leave. I also was thinking that maybe I should shape the duct/guard so that it had a wider inlet than outlet but I think that can be a revision for later and I'll just leave them vertical for now. I've read in my Fluids text book as well as on wikipedia, that I should incorporate stators to increase efficiency further and limit rotational forces. I realised a few days ago just before going to sleep that it would be best if these curved slightly to channel the fluid flow down rather than having it just hit a vertical wall. So I'm going to make these sort of a long-gated raindrop shape (picture above). These stators I'm going to put in a Y shape as it was also recommended to have a number that didn't have a common denominator with the number of blades of the rotor (I'm going to use 2 and 3 for rotor and stators retrospectively). The stators will also support the motor and be hollow so cabling can pass through them.For maintenance and ease of build, I'm going to build the duct itself in three separate pieces. These will be connected with joiners that will have the stators glued to them (not shown). The other end of the stators will be connected to the motor case/support. I haven't fully worked this out yet, as it depends on the motor somewhat, but I have just had an idea that, the case can also be a 3 part case which would allow the stators to be easily removed for repairs. This motor case would just be a cylinder with a top/lid that the motor is bolted onto.

Next the centre console. Centre console is just the bit in the middle where everything is connected too. Some of the names I use are just ones I've though up as I haven't found a glossary of all the terms I'm supposed to use. Another example of a word I'm using, is that I'm calling each of the arms/limbs that go out to the rotor assembly a branch. Anyway, I've worked out how I'm going to make the centre console including how to make it take out some of the vibrations for the rotors.

|

| Cut/slice view of centre console |

So firstly the branch bracket. This will be hollow for weight and ease of moulding. The back will be moulded separately so it can be built easily. The tube/branch will be glued into the bracket. The other end of the branch will be attached to the rotor assembly somehow, but I'm yet to workout how to attach it and make it separable in the future for maintenance. The picture above wasn't going to be combined, so that is why the blue picture looks out of place, but I thought it made sense to show it as an assembled piece next to the individual parts.

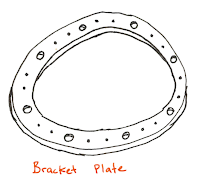

The branch brackets will then be attached to a plate like the one above with two screws on both the top and bottom. The larger holes in the plate are for the suspension bolts. I have drawn a picture for the sprung/base plate but it really doesn't show much other than a plate with eight holes in it for the bolts as I haven't designed any of the parts that go below the console or the bits that go inside.

The dome that goes over the top will come over the sides and down quite a bit so that it can be used to keep the weather off the internal components. Because of this, I put arches in the side so it can slide over the top of the branch brackets. I was originally going to have inside the dome, another set of supports, but I don't think it will actually need them, as the dome and 'bracket plate' should be able to cope with all the forces. The dome I'm thinking will be made out of plastic for ease of moulding and so one can look inside at the internals easily when on the ground.

Now Materials. As I've said in the past, I would prefer most of the design to be made out of fibreglass or carbon fibre. This though, is a material I've never used before so its going to be a steep learning curve for me I think, though it doesn't seem too hard to use once you know the basics. I'll obviously practise before I start building though. Thankfully, I've got mates at uni who said they are happy to help out as its such a cool project. I've also found out that some companies will route sheets of fibre for you such as this crowd in Victoria. I think for some of the objects, I want to make, it may be easiest to 3D print them first and then make a mould of them which can then be used for the fibre. I might be able to use this sort of technique for making objects such as rotors, as making a mould any other way would be very hard. With the rotor though, it might be easiest just to buy one first up though.

Most of the shapes I want to make though, I should be able to simply make in two halves and then glue together which isn't too hard. Another consideration when making most of these parts is obviously joining them. A few I can glue together but others this isn't an option as I want to make them maintainable by allowing them to come apart. The fix to this can be achieved by using metal buses that are glued into the parts and then can be tapped or drilled out to be used as nuts or straight holes. On my research about this, someone said you can place these in while making the part but I can't work out how this would easily be done. When drilling the holes for these bushes, it is also recommended to actually grind them out after the initial pilot hole as drilling can leave very sharp material that's frayed that can easily embed in the skin and be dangerous.

Well I'm only halfway through my notes! but I guess that didn't include pictures, but regardless still lots of ideas to come.

My next item on my list, is the camera mount/gimbal. Well firstly, I know actually know was a gimbal is. I'm part of a Facebook group for multi-rotor copters and people kept talking about gimbals and now I know what they are. So I think I will make one similar to the one in the picture below.

| AeriCam |

The Arducopter project has a very basic camera mount called the AC2 Camera mount. The interesting thing about this page though, is it talks about the settings of managing a camera mount so that could be useful for when designing/modifying code to run my copter.

As I've said in a previous post I would love to have a camera that I can control directly, and I've had a great idea that I might be able to buy an automatic lens for a SLR camera and be able to electronically control the zoom on it. I'm not sure if this is possible but would be a great way of incorporating a good quality zoom and would be much easier to upgrade the lens.

Bearings. Its come to my attention that a gimbal would also need bearings due to the weight, pivoting round. The other, and more important place I'm thinking to put bearings is on the rotors. This is so I can use the bearings as a way to keep water off the motors. The sort of bearings needed for the rotors will need to be self lubricating as any other sort would likely fail relatively quickly, and failure mid air is not something that is desirable.

Now some electrical influences of on the mechanical design. This is really about the physical needs of the power system. i.e. I need to remember that I actually need to power this thing so I can't forgot about where I'm going to store the batteries (and maybe in the future, the hydrogen storage and fuel cell). I think the battery should be able to fit inside the centre console if I make it large enough, otherwise it will have to be underneath the sprung plate, maybe in its own enclosure. I think the own enclosure is probably the best way to go as its much easier to change for different power sources. For example it can just be unbolted and a new designed bolted back on, just as long as the mount is standard. Though, if a battery does fit inside the centre console that would be great for weight. An idea that came from reading the rules of the UAV outback challenge, is to cushion the battery. This is so if the copter does crash, it doesn't also start a fire. (If you look on Youtube for Catalyst UAV Outback challenge, it comes up with a tv segment on the event and one of the UAVs it shows, does go up in smoke.)

Well that's finally the mechanical ideas done, now some electronics. First up, more sensors. Well I found that both Sparkfun and LittleBird Electronics, both have cheap ultra sonic sensors. I thought these were very expensive but being less that $20 rather than $200+ which I thought they were, I might use some eventually.

Next, I've though realised that I need some way of telling if its actually landed or not, so a couple of microswitches on the landing gear/legs should do the trick. I'm thinking if I use legs for landing, then it would just be a simple sprung leg system, that would spring away from the switch after take-off. I.e. closed when landed and open when flying. In this case, it is actually better to have the default mode not landed for when it breaks, so it doesn't accidently shutdown mid air, the safety guards/duct in the rotors should stop any injuries if the rotors are still spinning on the ground.

Next radio and communications. I started thinking about this a bit more after Farnell posted on their facebook page, a link to the ANAREN - A110LR09C00GM module which looked like could be a good basic module for transmitting data. Upon further inspection, I don't think it actually is quite in the right band for Australia so may not be worth it. In the upside, it uses a TI CC110LRTKT and this can be set to use anything from 300MHz to 928MHz so this could be set to comply with the regulations in Australia.

For controlling the copter, I'm thinking I'll start off with the 900MHz ISM band for controlling and then maybe buy the right to operate in another spectrum if it isn't too expensive. The other idea if this doesn't work out and may be better anyway, is to just use the 900MHz ISM band for control and then use 2.4GHz or 5.8GHz for video streaming.

I also found out in my five minutes of research into this technology that rather than using op amps or instrumental amps, there is actually RF (radio frequency) amplifiers that are designed for amplifying the signal that go in and out of the chip sets for radio communications.

The last idea for radio related ideas, is the controller. I mentioned this briefly in the last post but I think an XBox or similar controller would be excellent for controlling the copter. General movement could be the two joysticks, height control could be say R1 and R2 for up and down, the start button could be used for take off and starting the motors and turning the motors off after landing. It should be easy enough to convert from the USB output to a format easily read by a microcontroller or computer. Could even, rip out the internals and just just the buttons, joysticks etc and program it myself. Obviously, XBox controllers might not be that great to break into or connect to a computer so a generic controller would also suffice.

Next SMD circuits. Another of the many things I'm going to try and do after exams is make a SMD circuit building setup. I found a video that shows how to use the tin from tin cans (soft drink cans) for solder SMD stencils as its the correct thickness. This would be great as I wouldn't have to buy stencils and we (as in my household) get through quite a few cans so would be very cheap. To do this though, I would use an etching tank. I think I will buy one rather than use dad's tray based one as from what I understand, bubble tanks work much better than baths. The tanks are only $100 so not that expensive being capital equipment. The step after this is to setup reflow. Now I was thinking of doing this using a hotplate but I decided last weekend that, that was not going to get the right temperature curve so I'm going to do the standard home-brew idea of getting a toaster oven and converting it. I found a few online (though each retailer seems to only ever have one brand) and the best I found I think is one from KMart. Others I found were from Harvey Norman, Officeworks and Target. I'll work out how to convert from these instructions/tutorials here (Sparkfun), here (Freetronics) and here (Ben Heck).

That's it for electronics related to directly related to the copter but I have a few other electronics bits and pieces. Firstly, I found that ST have a guide on their site for tools/libraries for certain functions such as ethernet. Its lists opensource libraries along with the closed source ones so its good for commercial and hobbyist alike. Its available on Firmware page under Presentations & Training Material as STM32 and STM8 embedded software solutions on the same page you download peripherals libraries from.

I've also found a community site for STM32 chips but it doesn't seem to have much of a community feel to be honest. I did only have a quick look round but didn't seem to be anywhere near as welcoming as say AVR Freaks.

So that is finally the end of this post. I think sometime I may have to consolidate some of these posts into one so I don't have ideas about topics running over multiple posts with inter mingled topics. Anyway that's all for now, I'm still working on programming tutorials for the STM32. The first one will explain what all the files in the sample project do and might also do a flashing LED sequence. So if you got this far, Thanks for Reading! Signing out...